MISON® shielding gases

Achieve exceptional welding results with MISON® gas – cleaner welds, greater productivity and a safer workplace!

QUALITY

HIGH QUALITY

By minimizing oxidation and residue formation in the weld metal, MISON® ensures excellent surface finish and stronger bonds. This quality makes MISON® shielding gases ideal for both decorative projects and high-strength construction application.

EASIER TO WELD

MISON® shielding gases create a stable and smooth arc, enabling precise welding. With a stable arc, the welding process becomes more fluid and manageable, allowing better control over the weld pool.

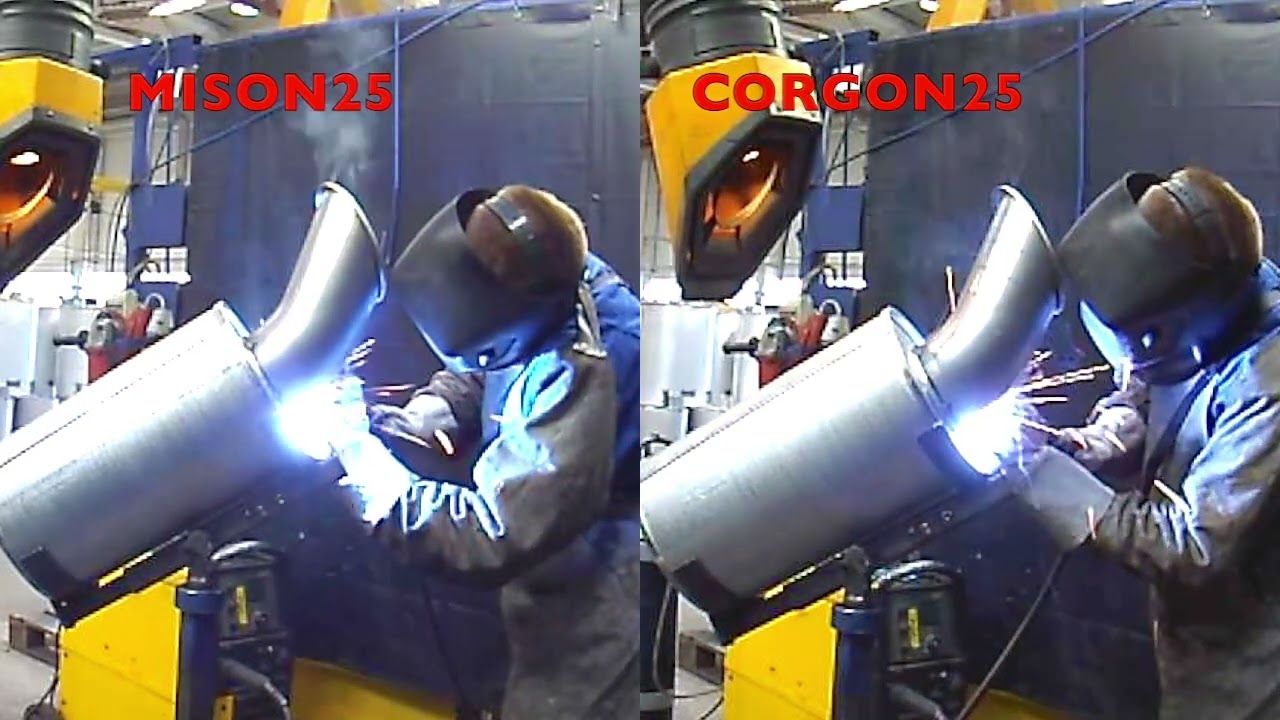

LESS SPATTER

MISON® shielding gases significantly decrease spatter welding, keeping the welding area clean and reducing the need for additional grinding. Fewer splashes also mean less damage to metal surfaces.

LOW MOISTURE LEVEL

The composition of MISON® shielding gases ensures extremely low moisture levels during welding, reducing hydrogen diffusion in the weld seam. This is crucial for preventing weld metal cracking and ensuring weld strength.

PRODUCTIVITY

FASTER WELDING

Thanks to consistent performance, the welding process is faster and smoother, requiring less time to complete a single weld seam. Shorter working time improves productivity and reduces costs.

BETTER PRODUCTIVITY

The stability, high quality, and reduced need for post-processing (like grinding or surface cleaning) offered by MISON® shielding gases enhance efficiency. This makes them an excellent choice for industrial production where every minute counts.

ENVIRONMENT AND PEOPLE

REDUCED ENVORINMENTAL IMPACT

Due to optimized gas composition, MISON® shielding gases have a smaller ecological footprint compared to alternatives. Reduced emissions result in a more environmentally sustainable welding process.

HEALTH-FRIENDLY WORKPLACE

Protect the welder from the harmful effects of ozone! Ozone is a strongly oxidizing gas that is generated during welding and is harmful to health.

General symtoms of ozone exposure: eye and throat irritation, cough, headache, lung damage, breathing difficulties.

MISON® shielding gases contain carefully dosed nitrogen monoxide that reacts with ozone, converting it into oxygen and nitrogen dioxide immediately. This minimizes harmful fumes and ozone levels, ensuring a safer and healthier welding environment.

EXPLORE THE WIDE RANGE OF MISON GASES AND CHOOSE THE WELDING GAS THAT SUITS YOUR NEEDS

Find out easily and quickly which shielding gas is best match for your welding materials and methods. Our shielding gas guide helps you choose the right shielding gas for your welding process from MIG/MAG welding to TIG.

Get in touch with us!

EXPLORE ADDITIONAL MISON® PRODUCTS THAT MAKE YOUR PROCESSES FASTER AND MORE EFFECTIVE

GENIE® 300 bar

GENIE® is an innovative and lightweight gas cylinder that holds more gas due to its higher pressure, requiring less frequent replacements. Its ergonomic design and reduced weight minimize strain on the back, hips, and wrists. The digital display makes it easy to monitor remaining gas levels, allowing for more efficient workday planning.

EVOS ViPR MISON® 18 300 bar

The EVOS ViPR MISON 18 gas cylinder features an integrated regulator, making it simple, fast, and safe to use. With a working pressure of 300 bar, the 50L cylinder holds more gas than traditional 200-bar cylinders, meaning fewer replacements and smoother workflows.

Its innovative design allows for quick and safe connections, while the built-in opening and closing mechanism ensures reliable performance.

FOR THE BEST OFFER AND MORE INFORMATION, CONTACT US!

Whether you want to test the product yourself or need assistance in determining the best solution through material testing, our team is ready to help with product demonstrations and expert guidance tailored to your needs.

MISON® brochure

Linde's shielding gases brochure

Linde's webpage

®MISON is a registered trademark of Linde plc.